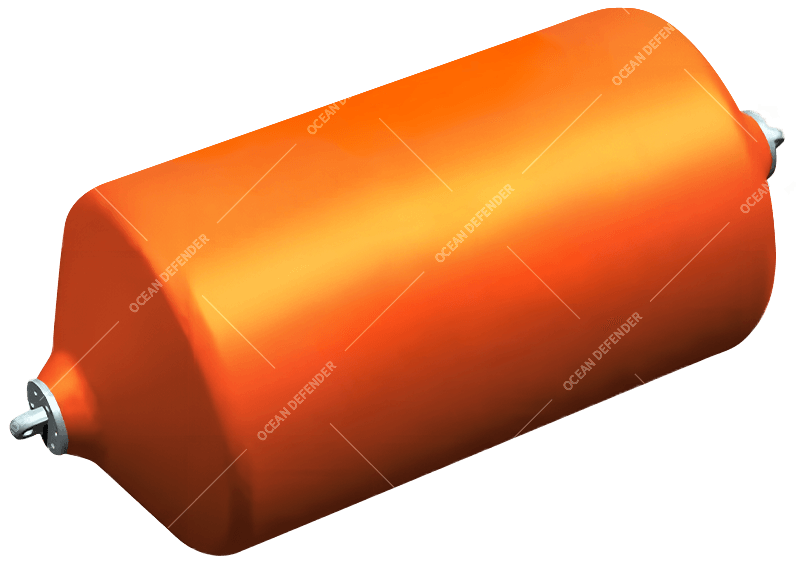

Ocean Armored-Defender

Net Type Foam Fender

NANHAI is the exclusive manufacturer of “Ocean Armored-Defender” (Net foam fender) and “Ocean Defender” (Netless foam fender) which have the world today leading & professional high-tech raw materials and unique production technology. Ocean Armored-Defender reflect the excellent fendering design and functionality. "Superior Guarantee, Supreme Guard"

Ocean Armored-Defender is an upgraded product of Ocean Defender, this “Armor” once again improves the protection performance of fender and prolongs the service life. This heavy duty foam fender quite suitable for rough berthing conditions.

Ocean Armored-Defender Applications

- LNG and oil terminals

- Ship-to-ship operations

- Offshore boat landings

- Military applications

- Shipyards

- Heavy duty operations

Ocean Armored-Defender Features

- Suitable for rough conditions

- Low reaction and high energy

- Virtually indestructible, won't be burst

- Anti-UV, Anti-acid, alkali and salt

- Wide range of standard & custom sizes

- Truck Tire Net/Aircraft Tire Net Optional

Ocean Armored-Defender Structural Design

Ocean Armored-Defender can reflect unparalleled performance, mainly due to the fender Excellent Structural Design, Superior Original Material and World-Leading Production Technology.

- 01-Closed Cell Foam Core (100%)

- 02-Nylon Filament Reinforcement Layer

- 03-Corrosion Resistance Polyurethane Skin

- 04-Heavy Duty Internal Structure

- 05-Heavy Duty Chain Tyre Net

01 Closed Cell Foam Core (100%)

Due to the molecular structure of Closed Cell (Isolation of Gas), so the foam core can maintain excellent elasticity which is the basis of foam fender performance. Ocean Armored-Defender utilizing only cross-linked, closed cell polyethylene.

02 Nylon Filament Reinforcement

Ocean Armored-Defender is constructed Continuous Tough and Thick Nylon Filament Reinforcement in Polyurethane skin which provides superior strength.

03 Corrosion Resistance Polyurethane Skin

High performance Polyurethane skin: Anti-acid, Alkali and salt corrosion, Anti-UV resistant, Non-marking which makes the Ocean Armored-Defender skin extremely durable to all types of weather, forces and marine conditions.

04 Heavy Duty Internal Structure

Heavy Duty Chain Connecting Swivel End Fitting Type (The internal chain guarantees maximum pull-through strength, even distribution of energy and stresses.) and Heavy Duty Internal Pipe Fixed End Fitting Type optional. All fittings are constructed of top-quality steel.

05 Heavy Duty Chain Tyre Net

Ocean Armored-Defender equipped with truck tyre net or aircraft tyre net optional. Heavy duty fittings include chains, shackles, flanges are all hot dip galvanized to ensure corrosion resistance and high strength.

Ocean Armored-Defender World Leading Production Technology

Lamination Process (Main Process)

Lamination Process

Laminated Process

Molding Process

Filaments Winding

Spraying Process

Equipped Chain Tyre Net

Heating Laminated Process (Main Process)

Cutting Process

Heat Laminated

Molding Process

Filaments Winding

Spraying Process

Equipped Chain Tyre Net

Ocean Armored-Defender Performance Spec. and Related Resources

Do you have any question?

Ocean Armored-Defender Qualifications and Certifications

SHANDONG NANHAI AIRBAG ENGINEERING CO.,LTD. established since 2006, which is the international leading manufacturer in marine fender and marine airbag production. NANHAI is also the China leading brand in offshore buoyancy engineering industry. Company focuses on various areas including port infrastructure, berthing and mooring, offshore floating structure R&D, design and technology application ( offshore wind power, marine aquaculture, oil and gas, bridge protection, etc. ) After nearly 20 years of development, product and technology applications have covered more than 80 countries and regions in 7 continents, NANHAI became the well-known brand in the world.

ISO 9001:2015

ISO 14001:2015

ISO 45001:2018

BV Certifications

Would you like to know more about Ocean Defender?

Contact us now!

NANHAI Other Marine Industrial Forms

The development of NANHAI during the past 20 years has involved many maritime fields, providing global customers with overall solutions for Berthing, Mooring, Ship to Ship, Ocean Wind Power, Deep-Sea Farming, Buoyancy and Salvage, Bridge Blocking, Ship Launching, Dock Caisson Moving etc.