Chile Navy Ocean Defender Trial Order

2022年10月22日

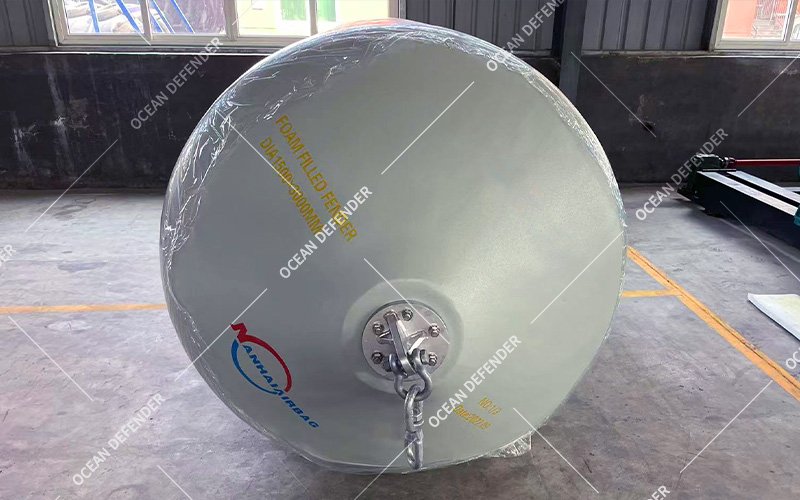

The hazards of low-quality foam fenders

2023年2月1日Foam fenders have a wide range of applications and a broad product market, so there are a large number of product manufacturers, but the quality on the market is uneven. In order to reduce costs, the products lose their basic performance of energy absorption and reaction force, and a large number of accidents caused damage to berthed vessels or impacts on piers. At the same time, due to the high value of the foam fender itself, users suffered huge economic losses.

For Example:

- Foam fender produced according to lower tolerances to reduce costs.

- Misleading customers on the basis of foam core density, combined with price (Learn More).

- Windingstructure foam core: low cost, poor performance of energy absorption and reaction force (Used by most manufacturers).

- The foam core is made of mixed density material, which has low cost and low performance.

- The foam core is directly filled with waste materials, which loses the basic performance of foam fender.

- Using poor qualitycentral axis, low cost, low strength, easy to break.

- Central axis is filled with scrap steel sand/cement to meet the weight requirements of customer.

The above situations exist alone or at the same time. Customers must understand clearly before making a decision when purchasing, otherwise it will bring you a large economic loss. Find us to know more.